Meltblown is one of the most specific and special products in Nonwoven industry. The mode of production gives the product its name.

It is mainly produced by the use of high-speed hot air with polypropylene raw material which is brought to a special high fluidity.

Due to its use in disposable products, it is very important for our world that it is made of recyclable raw material.

This fabric we often hear the name of in today's time, as the use of masks becomes mandatory, is produced under surveillance of our experts in our high-tech machines, so that it can prevent the epidemic as a result of R&D studies to ensure high filtration values at the highest levels.

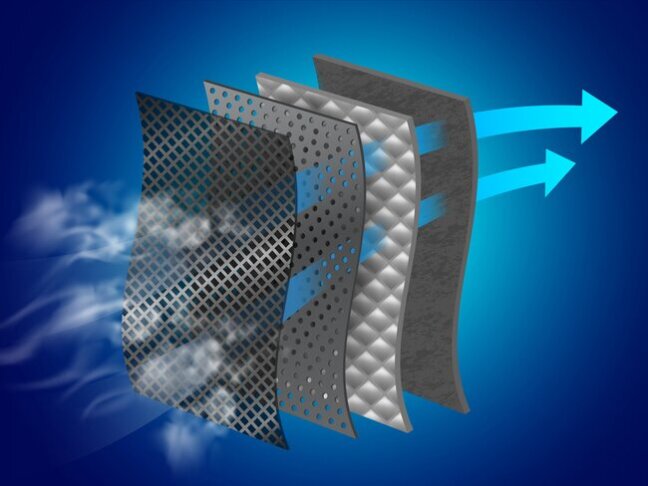

Meltblown is produced under high hygiene conditions, packaged untouched and then shipped to the user. Other areas of use are as follows; in all areas where filtering is required, it secures retention up to 0.3 microns particle level. In addition, it is very important for the hygiene of your facilities in the industrial area that it provides oil absorbing properties up to 16 times its weight.

Due to water repellent properties of its texture up to a certain pressure makes it a unique tool for cleaning oil and derivatives accumulated on the surface of water (since the oil spreads on the water and not mixes with). Moreover, it has a certain property of sound insulation, and with this property it is also used as an insulating material. In addition to all these properties, fire resistance up to a certain temperature is another reason for preference.